Ahmedabad-based Ishitva works on AI-enabled solutions to end rag picking forever

Ishitva Robotic Solutions is an Ahmedabad-based start-up providing AI-enabled waste collection and segregation machines. From plastic to glass to paper to rubber to hazardous biomedical waste, Ishitva works with various kinds of municipal solid waste.

By Nimisha S Pradeep

Hyderabad: Every time you drive past a landfill in a densely-populated city, you see men and women picking and sorting heaps of waste. Sometimes, it's not just adults but children who can be seen rag picking. Beyond that one-minute glimpse of their lives you get to see from your speeding vehicle, these people have to work amidst all kinds of waste, wet and dry, with their bare hands every other day.

When Jitesh Dadlani, a software engineer, saw the unhygienic lives that these people were living in his hometown of Ahmedabad, he was moved and he realised that this was a big problem that the entire country was facing. Jitesh, who always wanted to work with technology and innovate, thought we need a technology that can end rag picking forever and ensure decent lives for these people.

His timely meeting with his school friend Sandeep Patel helped him learn about the smart bins that Sandeep was working on. They initially set up 15 such smart bins in Ahmedabad. Jitesh realised that another big problem was that the country lacked a proper waste segregation mechanism and as a result, there was no proper recycling of wastes.

All these thoughts led to the birth of Ishitva Robotic Solutions, an Ahmedabad-based start-up providing AI-enabled waste collection and segregation machines. From plastic to glass to paper to rubber to hazardous biomedical waste, Ishitva works with various kinds of municipal solid waste.

"Ragpickers pick up waste with their bare hands. They work in dirty, unhygienic conditions. During the pandemic, I saw women and children picking up hazardous biomedical wastes with their hands. When we mechanise this whole process, these people can be employed for some other purpose in a safer space. If seven-eight people can segregate one tonne of dry waste in 8-10 hours, an AI-powered machine can finish five tonnes in an hour. At the collection part, it can do 5,000 picks (of garbage) per hour," says Jitesh.

Tech-solutions

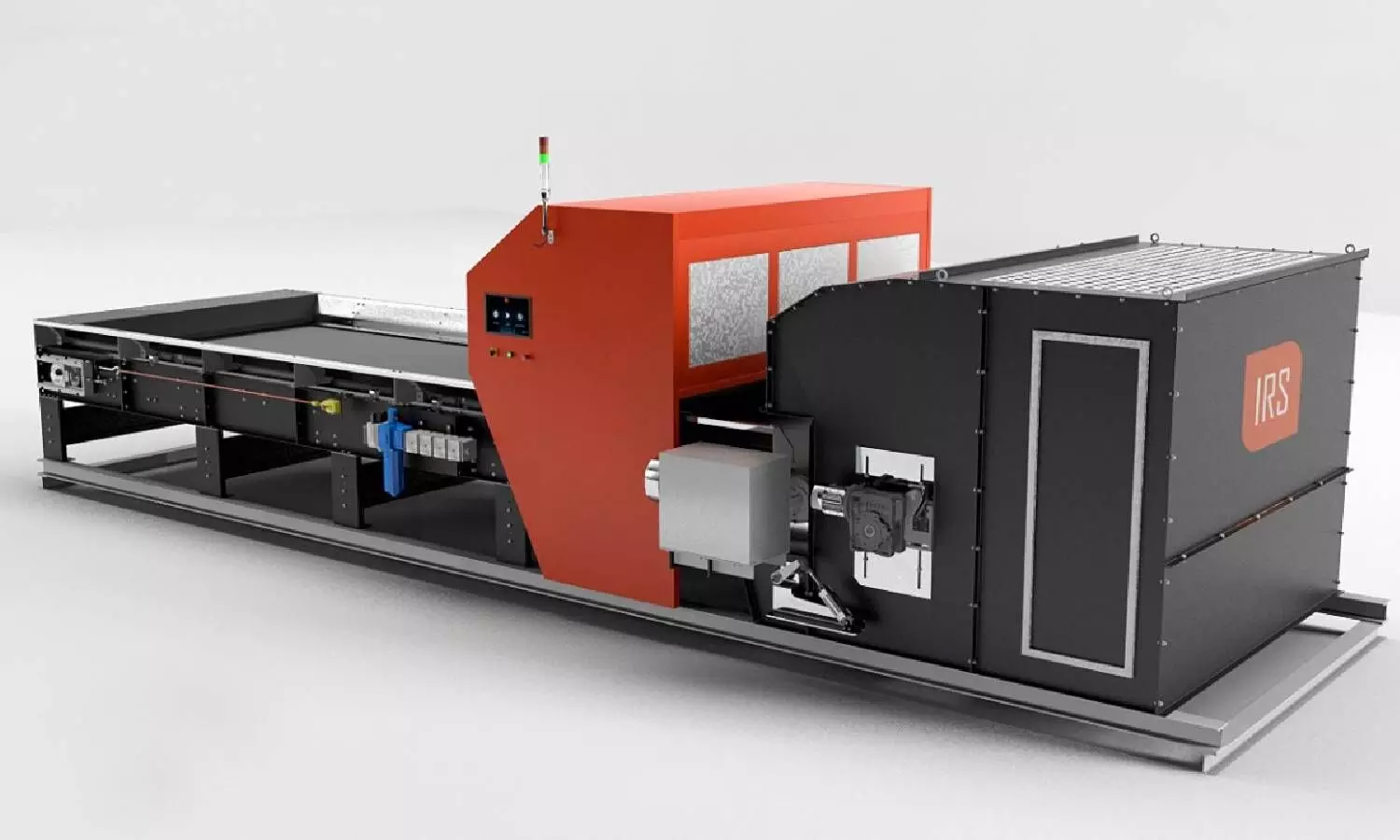

Ishitva mainly delivers four solutions – Netra or the machine vision system, Suka or the AI-powered air sorting system, Yuta or the AI-powered robotic sorting system, and Smart Bins or the IoT enabled bins.

Millions of images of recyclables with different polymers, brands, and colour categories are stored in Netra and are now being used at the material recovery facility (MRF) for dry waste sorting. "It provides insights and instruction for sorting and segregating operations of material insights and instructions for sorting and segregating operations flowing on any conveyor belt that usually needs a human for making decisions," explains Jitesh.

Suka on the other hand is the AI-powered air sorter, a high-speed mechanical sorting machine designed to handle high volumes of dry waste. It is a combination of high-speed conveyor belts and Netra.

Yuta is an industrial robot that can learn and adapt to any harsh environment to perform high-speed precision picking and placing of recyclables. Smart bins enable real-time data to monitor the efficiency of these dustbins.

nth degree segregation

"In 2016, the government started categorising waste into dry and wet waste and distributed separate bins for both. But still, there are various other kinds of waste that are grouped together. Like, say, among plastic itself, there are various kinds of plastic wastes like milk packets, Coca-Cola bottles, Harpic bottles, and various kinds of plastics like SDP, PET, etc. At Ishitva, we have an nth degree segregation mechanism that enables all Harpic bottles to be together and all sprite bottles together and likewise. This in turn helps in better recycling and the same Harpic bottle can be recycled into another new Harpic bottle. This ensures a circular economy," explains Jitesh.

Ishitva Robotic Solutions was one of the many companies that participated in INK@WASH 3.0 ((Innovations & New Knowledge in Water, Sanitation and Hygiene) held in Hyderabad on 5 and 6 May 2022. INK@WASH is a unique platform instituted by Telangana municipal administration and urban development for collaboration and partnerships between start-ups/innovators, mentors, academic institutions, non-profits, funders, and state/city governments.

NewsMeter is the formal media partner for INK@WASH 3.0. This article has been written by NewsMeter in association with the Administration Staff College of India (ASCI).