IIT-Hyd develop drug to treat black fever

By Anurag Mallick

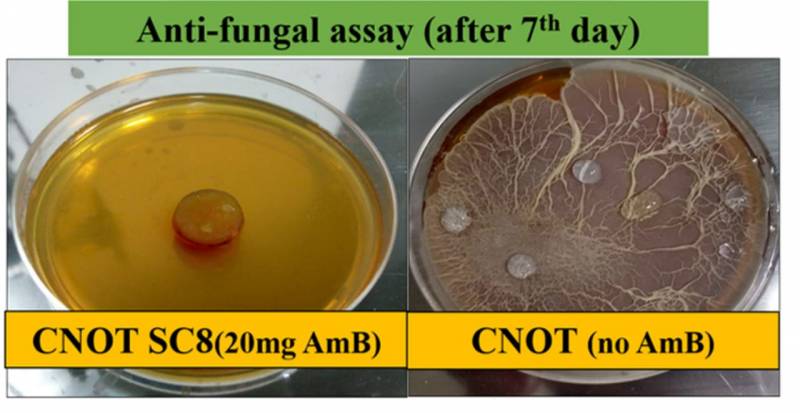

Hyderabad: The Indian Institute of Technology (IIT) Hyderabad Researchers have developed a method to produce controlled-release oral tablets for treating fungal infections and leishmaniasis (kala-azar or black fever) that are prevalent in the country.

Their tablets were found to release the drug Amphotericin B in a sustained and controlled manner over a period of 10 days. The research was led by Prof. Saptarshi Majumdar and Dr Chandra Shekhar Sharma, associate professor, Creative and Advanced Research Based On Nanomaterials (CARBON) Laboratory, Department of Chemical Engineering, IIT Hyderabad.

Prof. Brahmchari, who first used an antimony compound for treating kala-azar in the 1920s was nominated for the Nobel Prize in 1929. Kala-azar or black fever is a dangerous and often fatal form of leishmaniasis, common among the economically underprivileged sections in states like Bihar, Jharkhand, West Bengal & Uttar Pradesh. Amphotericin B (AmB) is the drug of choice for progressive and potentially life-threatening fungal infections of the abdomen and heart valves, fungal pneumonia, and leishmaniasis. The disadvantages associated with AmB include high cost, toxicity and poor bioavailability (<0.9%). Amb is administered through injection, which results in an uncontrolled release of the drug into the bloodstream.

Speaking on the rationale of using nanofibres to produce oral tablets of AmB, Dr Chandra Shekhar Sharma said, “Nanofibres – fibres that are a hundred thousand times thinner than the human hair – are increasingly being considered as a medium for controlled release of drug molecules because of their large surface area and porosity. There are two choices to be made in producing controlled-release tablets."

For the first, Dr Sharma’s team chose gelatine (or gelatin in American terminology), a U.S. Food and Drug Administration (FDA)-approved natural polymer, a form of collagen naturally found in the bones, cartilage, tendon and connecting tissues of animals. Gelatine is biodegradable, non-toxic and biocompatible and is extensively used in the food and medical industries.

For the manufacturing method, the team chose a process called ‘electrospinning.’ Electrospinning uses electric force to draw charged threads of the polymer into fibres with diameters in the order of some hundred nanometres.

The IIT Hyderabad team faced a small problem in making gelatine nanofibres by electrospinning. Dr Sharma said, “While gelatine nanofibres could be easily produced by electrospinning, their poor structural consistency in aqueous conditions required them to be crosslinked”. So the team found a way to crosslink the fibres.

One of the researchers Prof. Majumdar said, “Through careful control of the crosslinking conditions, we could achieve sustained release of AmB over 10 days.”