IIITH-KAUST research collaboration produces cost effective material for pressure sensors

Bubble-induced polydimethylsiloxane (PDMS) foam paired with conductive textile electrodes can be engineered into capacitive pressure sensors accoridng to IITH-KAUST

By - Newsmeter Network |

Hyderabad: A joint team of researchers from the International Institute of Information Technology, Hyderabad (IIITH) and King Abdullah University of Science and Technology (KAUST), Saudi Arabia, has reported the development of a flexible, low-cost material that could change how pressure sensors are designed for healthcare, robotics, and wearable devices.

Breakthrough Published in IEEE Journal

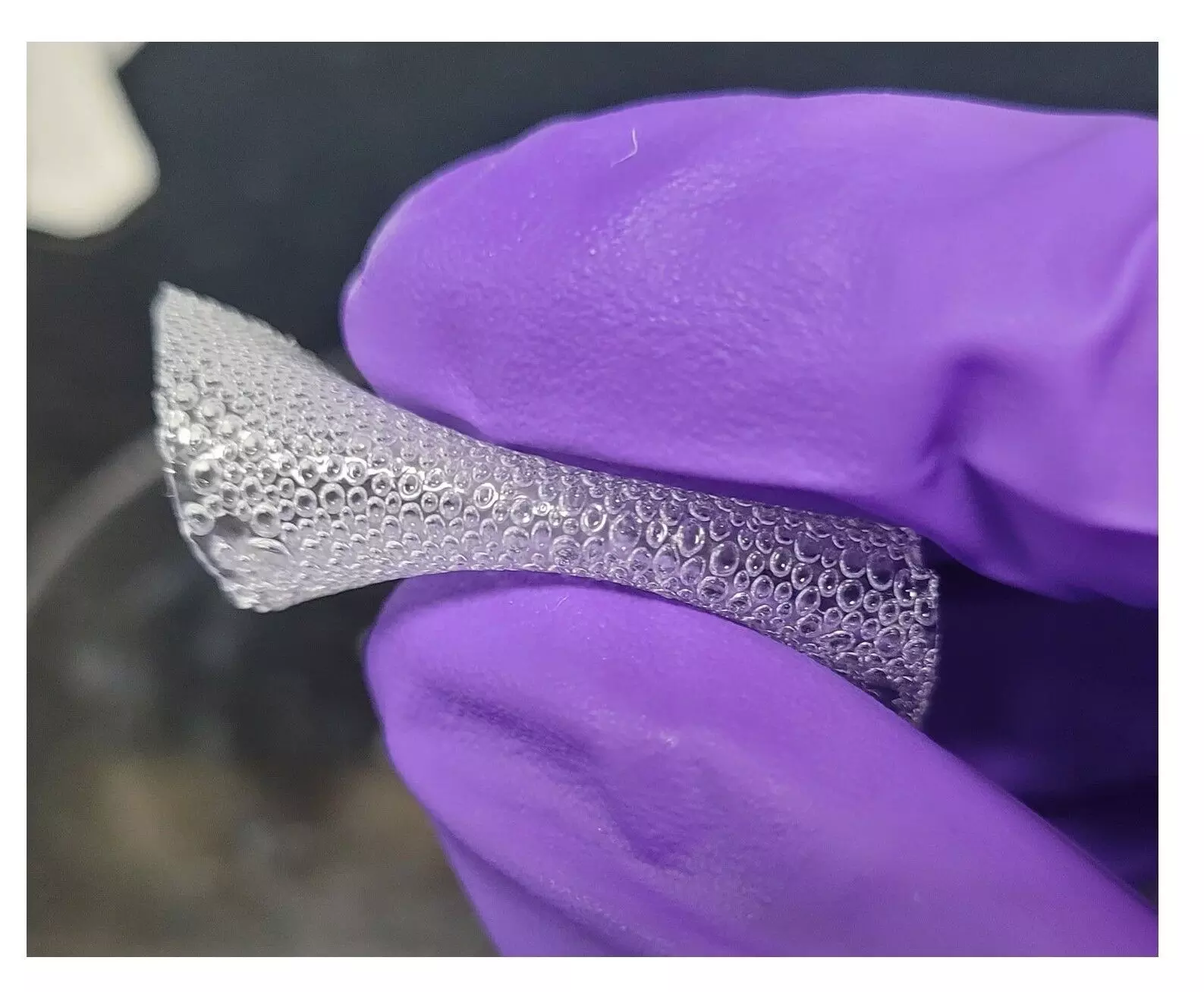

The findings, published in the IEEE Journal on Flexible Electronics, describe how bubble-induced polydimethylsiloxane (PDMS) foam paired with conductive textile electrodes can be engineered into capacitive pressure sensors that are inexpensive yet highly sensitive.

The sensors performed consistently across tests, showing potential for human–machine interaction, surgical robotics, and wearable technology.

“Everyday Materials” at the Core

Speaking on the fabrication method, Dr Aftab M. Hussain, Associate Professor at IIIT Hyderabad, said:

“Our fabrication approach uses everyday materials like cotton textiles and polymer foam, and still delivers performance comparable to state-of-the-art flexible sensors. The PDMS foam created in this study has far-reaching applications beyond sensors, because it is an emerging class of materials that provides more stretchability and flexibility than the base polymer. This opens up opportunities for affordable and customizable materials for healthcare and assistive technologies.”

How the Sensors Were Made

The team synthesized polypyrrole-coated conductive cotton textile using a simple chemical oxidative process. This was combined with bubble-trapped PDMS foam to create a compressible capacitive structure. The resulting sensors exhibited low hysteresis, strong repeatability, and rapid response, key features for reliable applications.

Tested in Real-World Scenarios

To illustrate practical use, the researchers demonstrated two prototypes:

• Computer interface: the sensor reliably detected single and double mouse clicks.

• Wearable glove: the sensor distinguished between grasping objects of different weights, indicating potential for robotic grip control and biomedical feedback.

Support and Next Steps

The project received partial support from the PURSE grant, Department of Science and Technology (DST), Government of India.

The researchers suggest that beyond robotics and healthcare, the material could have implications for tactile wearables and low-cost human–machine interfaces.

Paper Citation:

Saurabh B. Mishra, Nazek El-Atab, and Aftab M. Hussain, “Fabrication and Characterisation of Large Area Flexible Capacitive Pressure Sensors using PDMS Foam and Functionalized Textile,” IEEE Journal on Flexible Electronics, 2025. DOI: 10.1109/JFLEX.2025.3612874.